TERRALINE™ Duodec²

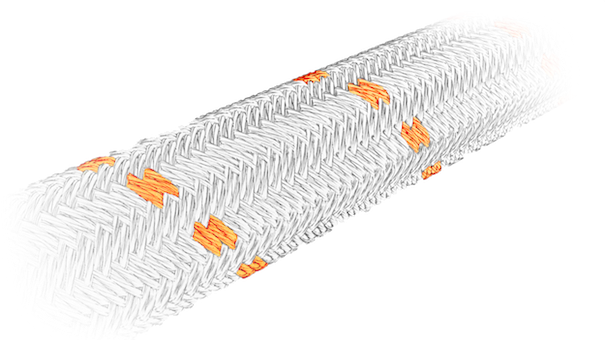

TERRALINE™ Duodec² Double braided 12-strand Polyester rope

Timm has produced great ropes since 1772, and we constructed the first polyester rope in 1952. Polyester is a particularly reliable fiber, and has proven to be the most durable of the conventional fibers used in ropes.

The engineers at Timm have managed to design a unique double braided, 12-strand polyester rope, which delivers over twice the strength of conventional polyester ropes–with a breaking strength 150% above ISO standard.

Rope testing with DNV GL – at the Ormen Lange testlab in Norway also proved that the subsea breaking strength (MBL) transcends the MBL from the standard ISO 2307 dry test procedure.

The peak performance of the Terraline

Duodec is obtained mainly through two key elements:

1. Super HT polyester bers

2. Unique 12-strand MaxLoad design

– twisting and laying of yarn and strands

The Timm engineers have combined the experience from Acera™ high performance HMPE ropes, with an innovative “twist” of the traditional 12-strand rope construction. This MaxLoad design is based on a set of unconventional yarn twist/strand laying/ rope design ratios, and the use of new tools for simultaneous tensioning of all laments, yarns and strands respectively.

Key Benefits

- High strength, both wet and dry

- Increased abrasion resistance

- Easy to handle

- Well balanced; 6 left and 6 right strands

- Low bending ratio

- High melting point (260°C)

Product Features

- Construction

-

12-strand plaited

24-braided cover - Fiber

- Polyethylene Terephthalate - Super HT Polyester Super High Tenacity and high adhesive

- Specific gravity

- 1,37 (sinking)

- Colours

- White

- UV resistance

- Excelent

- Abbrasion resistance

- Excelent

- Acid resistance

- Good

- Alkali resitance

- Good

- Cold & frost resistance

- Very Good +

- Water resistance

- Excellent (< 0,5% absorption)

- Heat resistance

- Excellent (260° melting)

- Elongation

- Moderate (10% at break)

- Colours polyester cover

- White

- Cold & frost resistance

- Very Good +

| diameter | MBL spliced | MBL spliced | MBL unspliced | MBL unspliced | diameter | MBL spliced | MBL unspliced |

|

DIA.

|

DIA.

|

||||||

| (mm) | (t) | (kN) | (t) | (kN) | (inch) | (lbs) | (lbs) |

| 10 | 4 | 39 | 4.4 | 43 | 13/32“ | 8.767 | 9.667 |

| 12 | 5.61 | 55 | 6.3 | 62 | 1/2“ | 12.364 | 13.938 |

| 14 | 7.7 | 75 | 8.5 | 83 | 9/16“ | 16.860 | 18.659 |

| 16 | 9.8 | 96 | 10.3 | 107 | 5/8“ | 21.580 | 24.054 |

| 18 | 12.3 | 121 | 13.7 | 134 | 3/4“ | 27.201 | 30.124 |

| 20 | 15.1 | 148 | 16.7 | 164 | 13/16“ | 33.271 | 36.869 |

| 22 | 18.2 | 178 | 20.1 | 197 | 7/8“ | 40.016 | 44.287 |

| 24 | 21.4 | 210 | 23.8 | 233 | 1“ | 47.142 | 52.380 |

| 26 | 25 | 245 | 27.7 | 272 | 1_1/16“ | 55.033 | 61.148 |

| 28 | 28.8 | 282 | 32 | 314 | 1_1/8“ | 63.531 | 70.590 |

| 30 | 32.9 | 322 | 36.5 | 358 | 1_1/4“ | 72.433 | 80.481 |

| 32 | 37.2 | 365 | 41.3 | 405 | 1_5/16“ | 81.943 | 91.047 |

| 34 | 41.8 | 410 | 46.4 | 455 | 1_3/8“ | 92.059 | 102.288 |

| 36 | 46.6 | 457 | 51.8 | 508 | 1_1/2“ | 102.782 | 114.203 |

| 38 | 51.7 | 507 | 57.5 | 564 | 1_9/16“ | 114.113 | 126.792 |

| 40 | 57.1 | 560 | 63.4 | 622 | 1_5/8“ | 125.848 | 139.831 |

| 44 | 68.6 | 672 | 76.2 | 747 | 1_3/4“ | 151.139 | 167.932 |

| 46 | 74.6 | 732 | 83 | 814 | 1_7/8“ | 164.695 | 182.994 |

| 48 | 81 | 795 | 90 | 883 | 2“ | 178.655 | 198.506 |

| 50 | 87.6 | 859 | 97.4 | 955 | 2_1/16“ | 193.223 | 214.692 |

| 52 | 94.5 | 927 | 105 | 1030 | 2_1/8“ | 208.397 | 231.553 |

| 56 | 108.9 | 1068 | 121 | 1187 | 2_1/4“ | 240.163 | 266.848 |

| 58 | 116.6 | 1143 | 129.5 | 1270 | 2_3/8“ | 256.956 | 285.507 |

| 60 | 124.4 | 1220 | 138.2 | 1355 | 2_1/2“ | 274.154 | 304.615 |

| 64 | 140.8 | 1381 | 156.4 | 1534 | 2_5/8“ | 310.370 | 344.856 |

| 68 | 158.2 | 1551 | 175.8 | 1724 | 2_3/4“ | 348.813 | 387.570 |

| 72 | 176.5 | 1731 | 196.2 | 1924 | 3“ | 389.278 | 432.531 |

| 76 | 195.8 | 1921 | 217.6 | 2134 | 3_1/8“ | 431.767 | 479.741 |

| 80 | 261.2 | 2120 | 240.1 | 2355 | 3_1/4“ | 476.481 | 529.424 |

| 84 | 237.4 | 2328 | 263.8 | 2587 | 3_1/2“ | 523.421 | 581.579 |

| 88 | 259.6 | 2546 | 288.5 | 2829 | 3_5/8“ | 572.385 | 635.983 |

| 92 | 282.8 | 2773 | 314.2 | 3081 | 3_3/4“ | 623.371 | 692.635 |

| 96 | 306.8 | 3009 | 340.9 | 3343 | 4“ | 676.381 | 751.534 |

Customer service

We have the local knowledge and industry expertise to find the best solution to cater for your needs, do not hesitate to get in touch and ask for an advice.

+421 32 640 17 13 timm-sales@wilhelmsen.comCertificate